The PVD technology offers excellent possibilities in decorative as well as in functional fields of application. The PVD processes with arc vaporisation and sputtering of different materials result in perfect surfaces, with not only brilliant quality of colours, but also excellent mechanical properties.

Physical Vapour Deposition is a process during which the target material is vaporised by bombardment with laser beams, magnetically refracted ions or electrons, as well as by arc discharge.

How many atoms, ions or larger clusters are in the vapour, varies from process to process. The vaporised material moves through the chamber either on trajectories or led by electric fields. It condenses on to the parts to be coated, thus forming a layer.

The layers deposited during the PVD process depend on the composition of reactive gases and target material, forming either nitrides or carbides, or mixtures of both. These layers offer a hardness of more than 2000 HV as well as very good scratch and abrasion resistance. Chemically as well as electro-chemically, these layers are very inert and guarantee protection against many corrosive agents.

Machines and plants for PVD coating

- PVD batch machines – max. usable volume:

Ø 1500 mm x 3000 mm Arc-/sputter technology - Inline coating machines – max. usable volume:

600 mm x 750 mm x 25 mm sputter technology

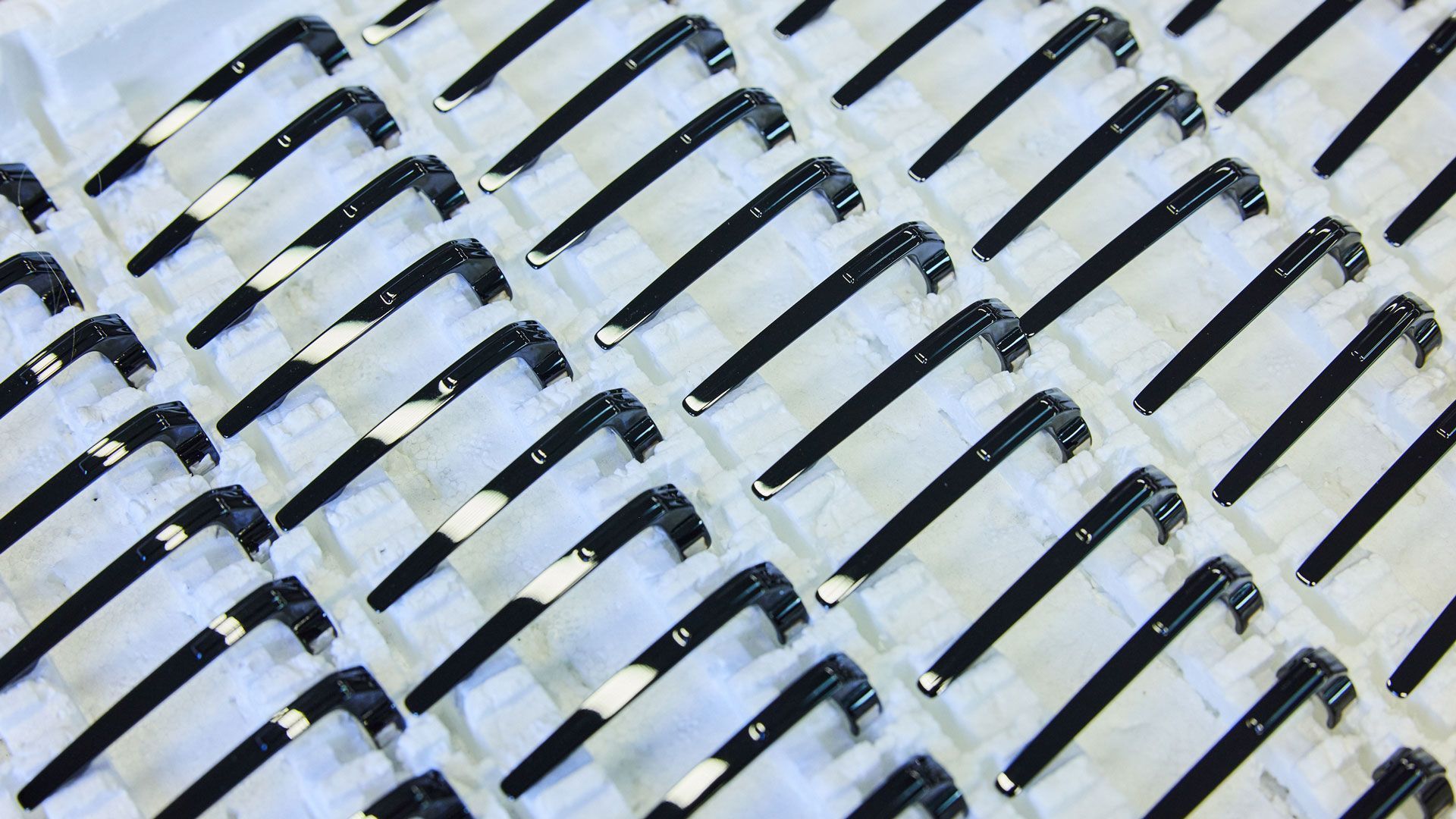

europcoating PVD coating

Benefits of PVD coating

- Brilliant colour quality

- Wide colour spectrum

- Excellent mechanical properties

- Cost-efficient serial production

- Non-polluting processes

- Biocompatible coating

Outstanding mechanical durability

Functional coatings

For high-quality product finishing europcoating has applications with excellent mechanical characteristics available. Functional coatings from europcoating offer mechanical protection and convince in medical applications as well as with electric functions and efficient barrier effects.

The demands on functional coatings are as multiple as their field of deployment. Therefore, we develop specific coating systems adapted to our customers’ individual requirements. europcoating has unsurpassed know-how in functional coatings with precious metals.

Our services in this area are nearly unique in the market.

Due to long years of experience in the most varied fields of application, we are able to offer complete solutions. That means for you that we are not only producing according to your requirements, but also offering our complete knowledge and extensive advice regarding all aspects of surface optimisation.

Highlights in surface treatment

Design coatings

Noble gloss and brilliant colour effects within the whole spectrum of visible light are the convincing features of the decorative coatings by europcoating. Coatings with pure gold belong to europcoating’s core competences. Surfaces with a layer of 24 carat of gold impart classic elegance to the treated products and increase their value.

Only few companies in the area of surface treatment may offer both professional technical know-how and experience in the treatment of jewellery and design products. Our expert team’s day-to-day business is the optical enhancement of high quality design products such as spectacle frames, watches, writing instruments and accessories by means of high-tech coating processes. With minimum deployment of material and a wafer-thin surface application, we give your products new properties – brilliant, hard and shiny.

There is a great variety of materials that can be treated. Besides metals and their alloys we also coat glass and plastics. We also deal with top-enamels, abrasive blasting and polishing, always aiming at bringing a maximum of beauty and expressiveness to the surface of your products.

Competence in precious metals: Exclusive products with coating of real gold

Coatings with pure gold are one of the noblest forms of surface design. One of europcoating’s core competences is the exclusive coating with pure gold. Surfaces of 24 carat gold impart classic elegance to your products and increase their value.

europcoating is market leader in the area of exclusive coatings with pure gold.

Specific coatings with pure metals can be produced to order, e.g. gold, champagne-gold and silver with a constant, reproducible colouring.

Brilliant surfaces of pure metals deposited by means of a PVD-process provide your products with unique gloss, constant brilliance of colours and maximum corrosion resistance. This way your products obtain an outstanding high quality finish, combining decorative requirements with the best mechanical properties.

Coatings for medical applications for instruments & implants

Surface finishing for medical use

Medical products are tested according to the strictest criteria. No other product sector in Germany is subject to higher requirements. In this context, coatings play a key role.

europcoating is a certified expert in the development and production of ultra-thin coating systems using PVD vacuum technology and the anodic oxidation of PVD coatings for medical technology applications.

At our corporate locations in Hohenlockstedt and Tuttlingen, we advise and develop surface solutions for use in medicine, tools, implants, prostheses and much more. Since 2013, we have been represented by our coating center at the Tuttlingen site, where innovative coatings for medical applications are exclusively developed and manufactured.

Certified product safety – QM system

europcoating has certified quality management systems according to DIN ISO 13485 & 9001, which are aligned to the special requirements in the medical device industry.

Cooperation with institutions and companies from science and research

Surfaces of both medical instruments and implants must be in direct contact with tissue. In order to meet these demanding standards, we work with experienced experts as well as with young scientists from the medical industry.

europcoating is also a member of the cooperation network "Kunstgelenk" (endoprosthetics).

europcoating surfaces for medical applications

Benefits of the europcoating surfaces

- Good resistance to mechanical and chemical influences

- High durability despite intensive washing and sterilization processes

- Certified biocompatibilty

- Pleasant feel

- Change of surface structure on request

- Color matching to customer requirements

Durable surfaces for industrial applications

DLC coating

DLC coatings have outstanding properties regarding reduction of wear, friction and corrosion. Therefore the DLC process is best suited for coating of components of tools and machinery supposed to be under dynamic load.

DLC coating often is named Diamond-Like-Carbon-coating. It is a diamond-like protective layer of carbon having outstanding mechanical properties. The extreme hardness of a DLC-coating guarantees good protection against wear, friction and corrosion and thus leads to a long service life of product surfaces. DLC-coatings are used for manifold applications in the areas of design and function.

A DLC-coating developed by europcoating guarantees an immediate improvement of the surface characteristics of your product. We appreciate guiding you to the possibilities of a tailor-made coating adopted for your product.

Machines and plants DLC coating

- 3 PVD batch machines – max. usable volume:

Ø 1500 mm x 3000 mm